Automatic Cable Winding

Retractible extension cords have helped to organize heavy-duty cables in garages/workshops for years now. Why hasn’t this technology been applied to the numerous cables we carry with us each day? Follow along for a live-look at my process to reverse engineer the mechanisms involved in this technology.

Prototype 1

Proof of Concept

Setting up the Basics

Determine Essential Components:

Bearings

Torsion Spring

Ratcheting mechanism with release

Cable Spool

Cable stop

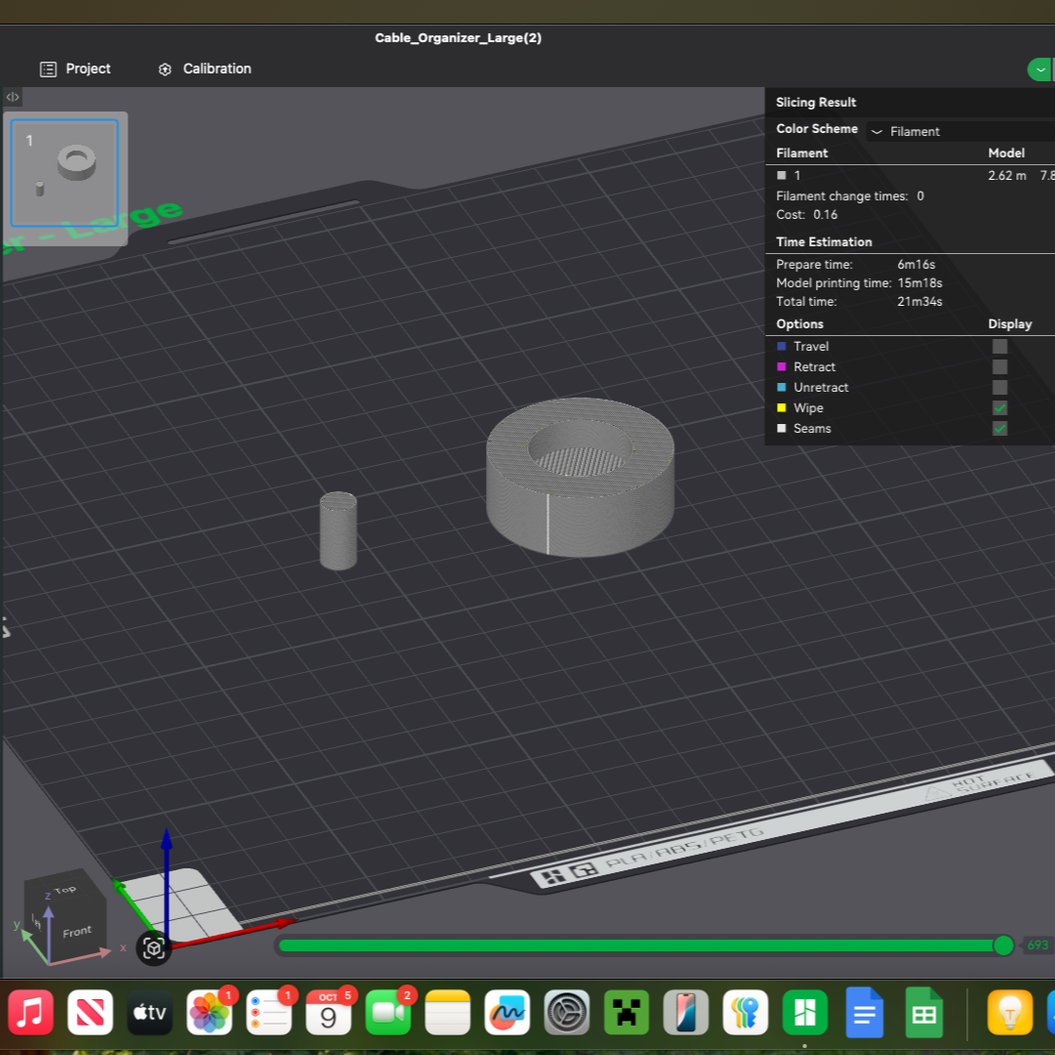

Test Print 1:

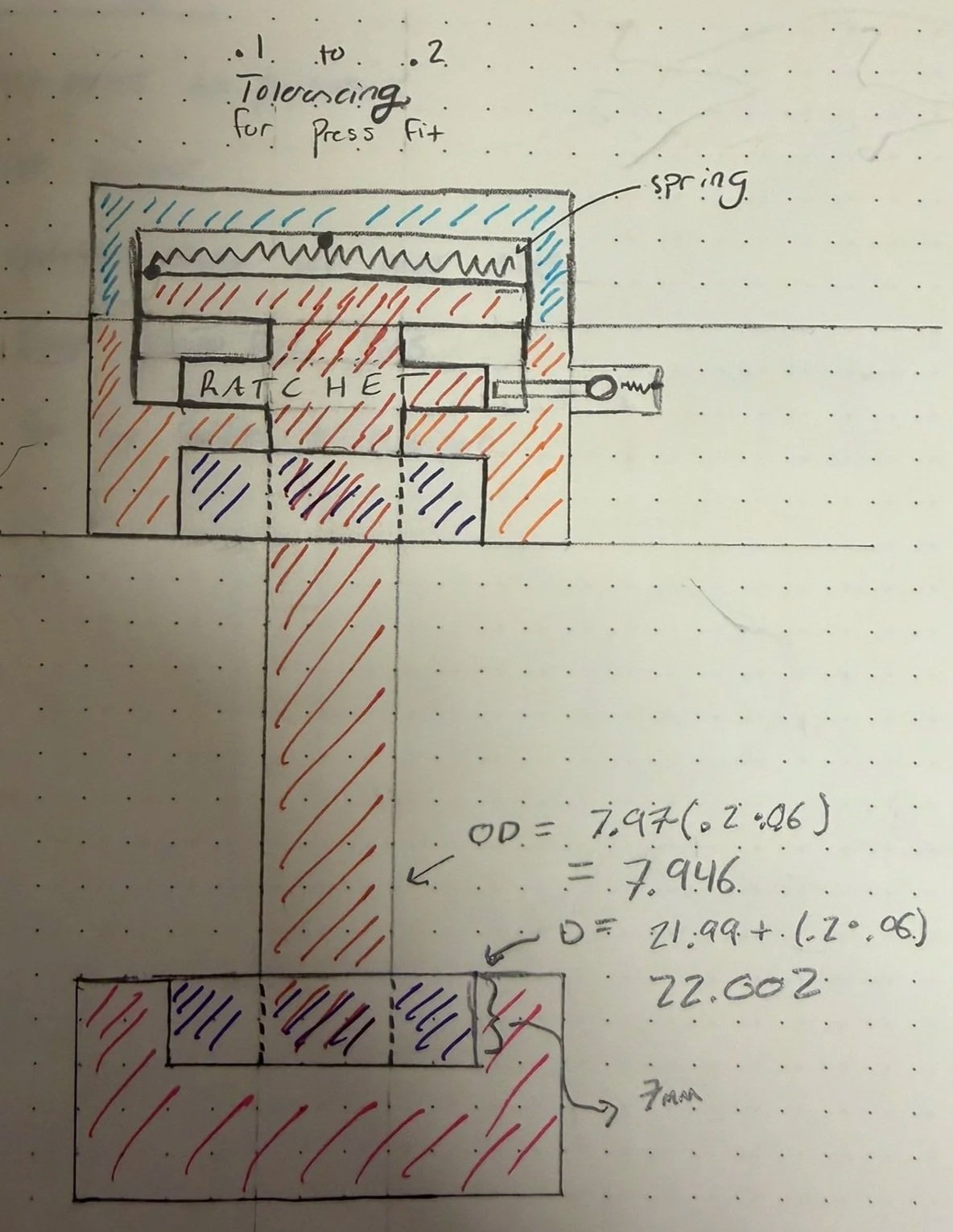

Figure out proper tolerancing for press fitting bearings with 3D printed parts

DFM, General Fit, General Geometry

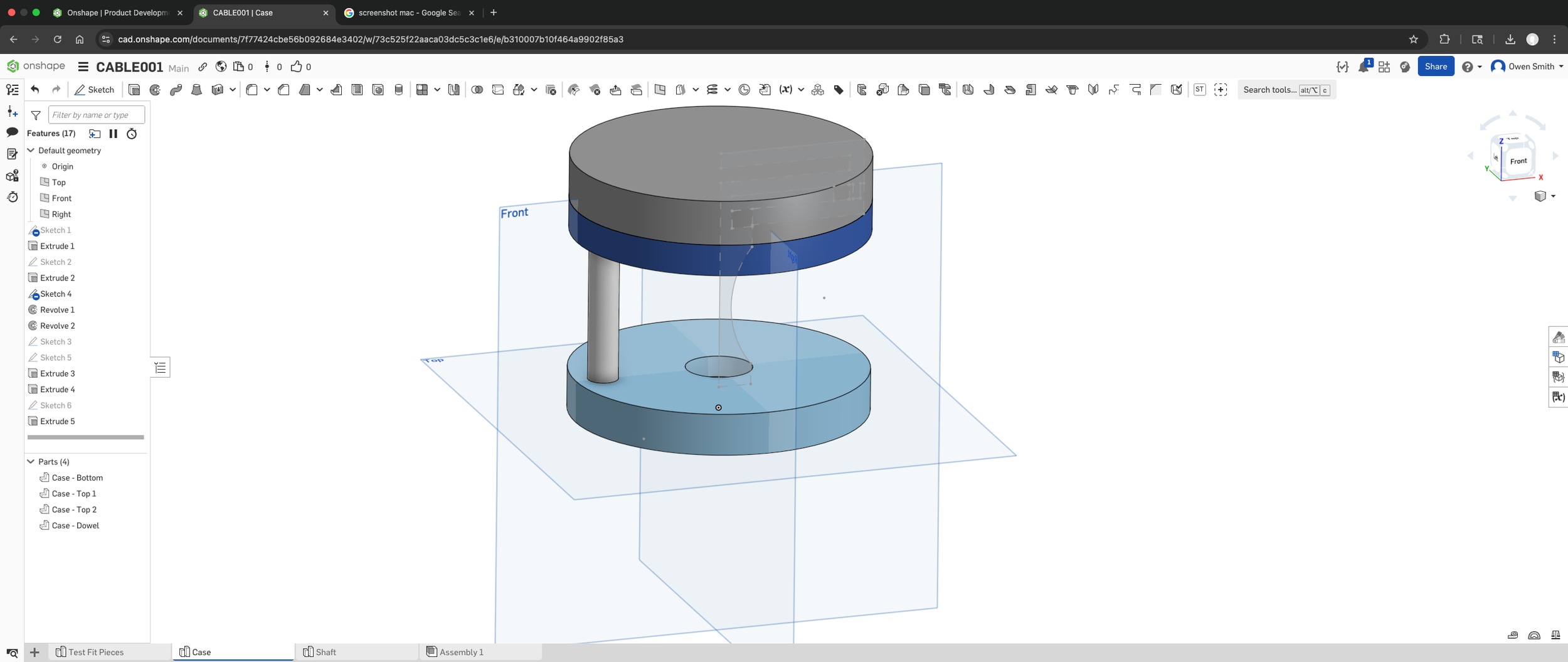

Establish General Sizing

Establish diameter of case to hold torsion spring, fully winded cable

Make sure tolerances ok for smooth rotation

Make pieces simple, easy to assemble

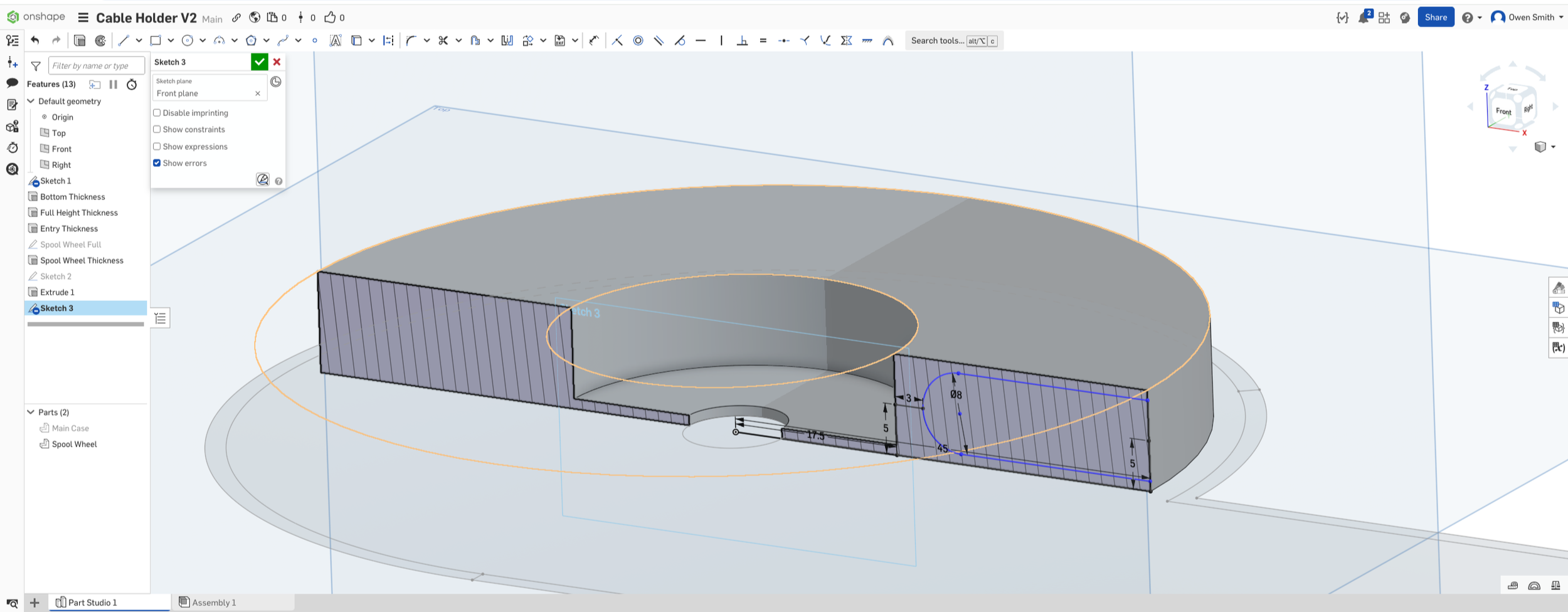

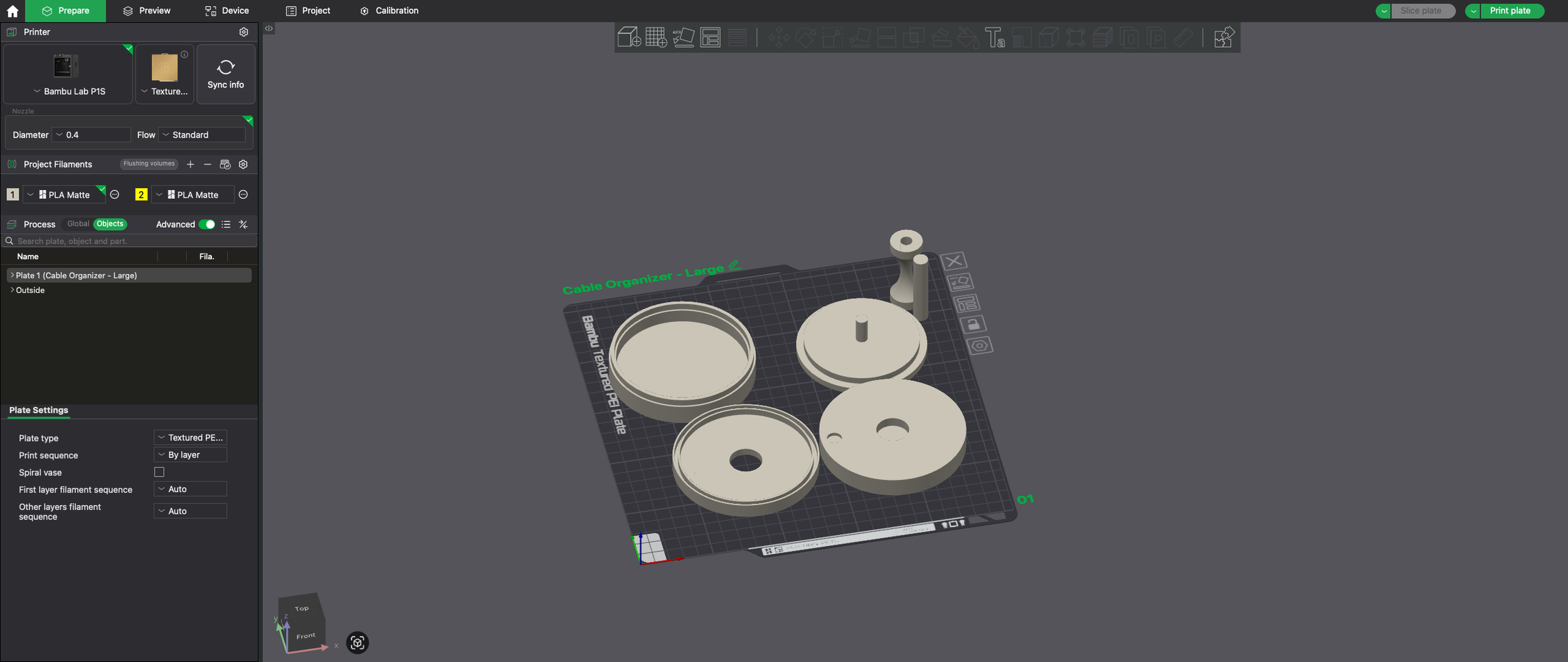

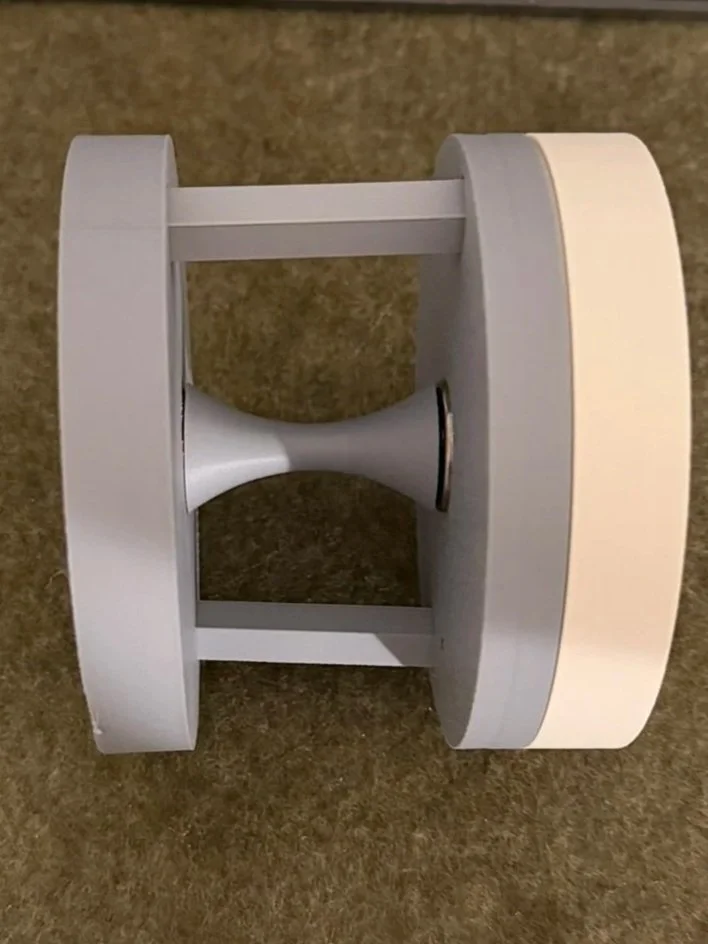

Test Print 2: Large Case Pieces

Simple design for large pieces. Allows for less re-prints to improve cost and time efficiency of mechanism design iteration

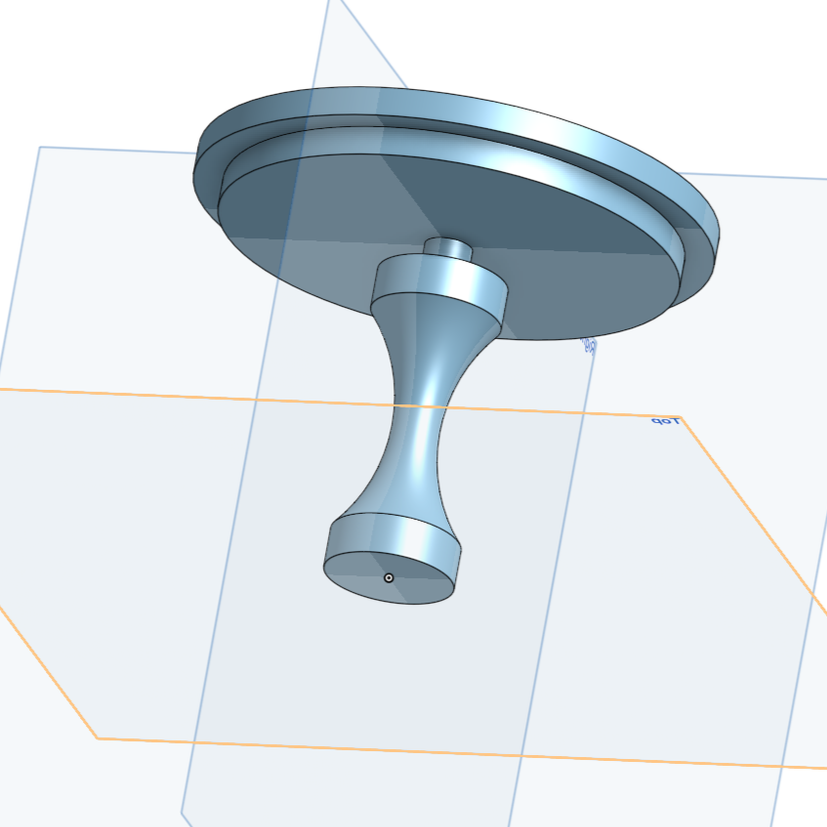

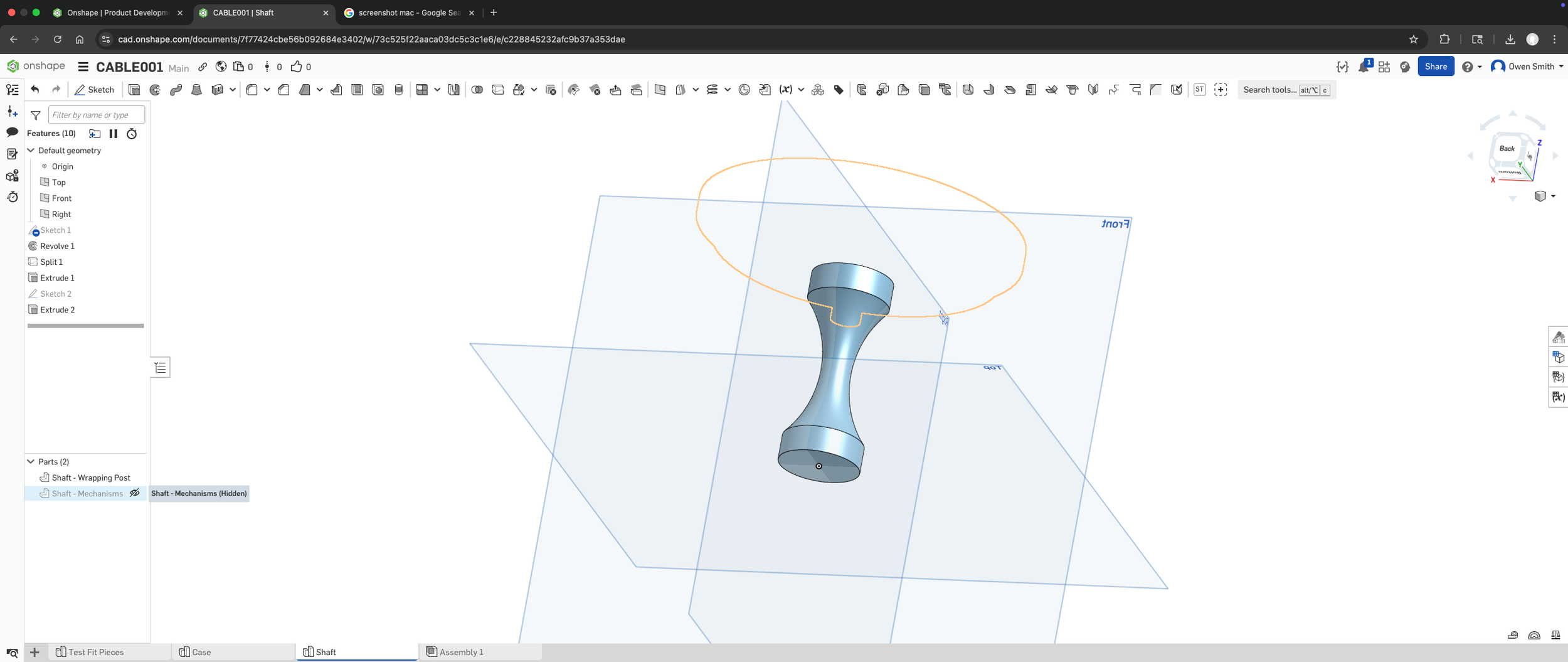

Spool Design

Determine how spool will interface with bearing and top case

Establish press fit Dimensions for 2 part spool

Test Fit, Draw Conclusions

Successes:

Proper diameter for full cable wind

Press fit dimensions for bearings

Easy to assemble, take apart, and print

Issues:

Spring Deformaility (switch to metal)

Design is clunky

Need ratcheting mechanism

Can drastically reduce pin-attachment style with heat set inserts/ screws

Prototype 2

Level up parts / Durability / Reduce Size / Address Cable Entry & Exit

V1 was fun, but now we’re really going for it!

Time To Get Serious

Procure Parts

Metal Torsion Spring from Lego Motor

Metal Pins from lego Motor

Basic spring for ratcheting mechanism

Heat Set Inserts (Metric)

Screw Set (Metric)

Soldering Iron

Test Print 1:

Figure out proper tolerancing for heat set inserts

~.5mm smaller diameter hole should suffice

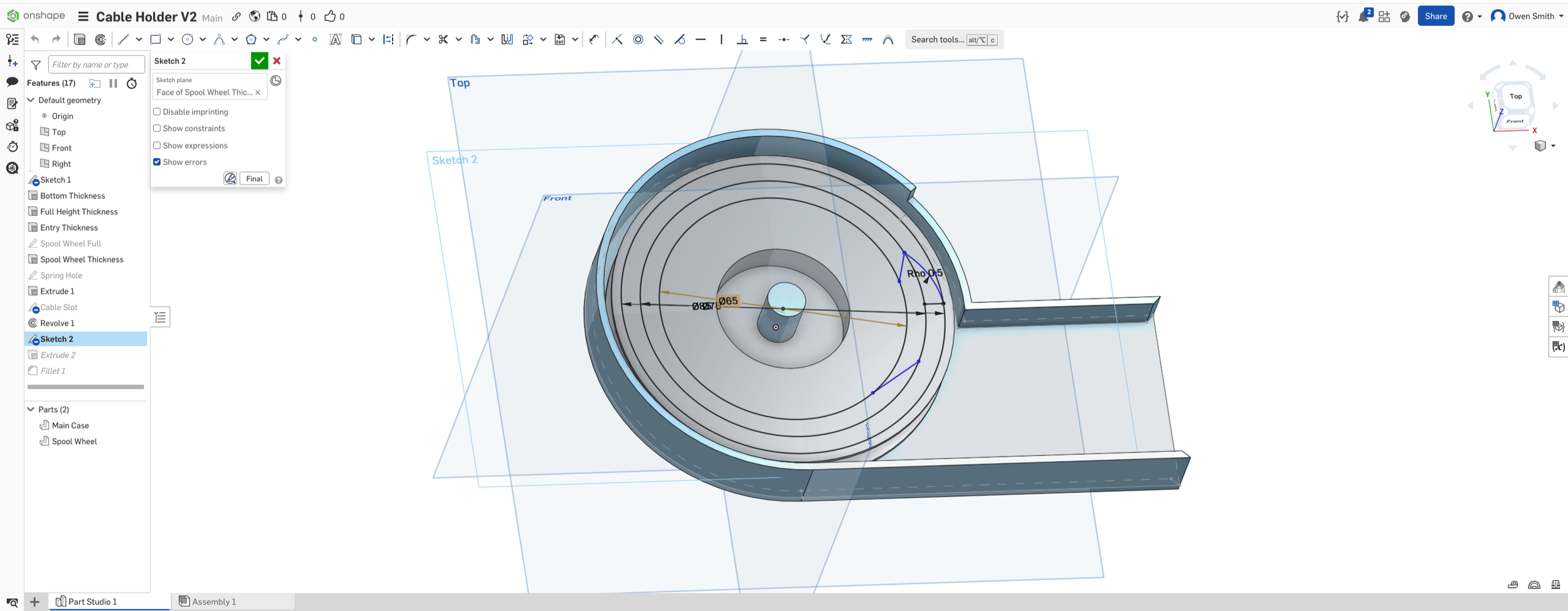

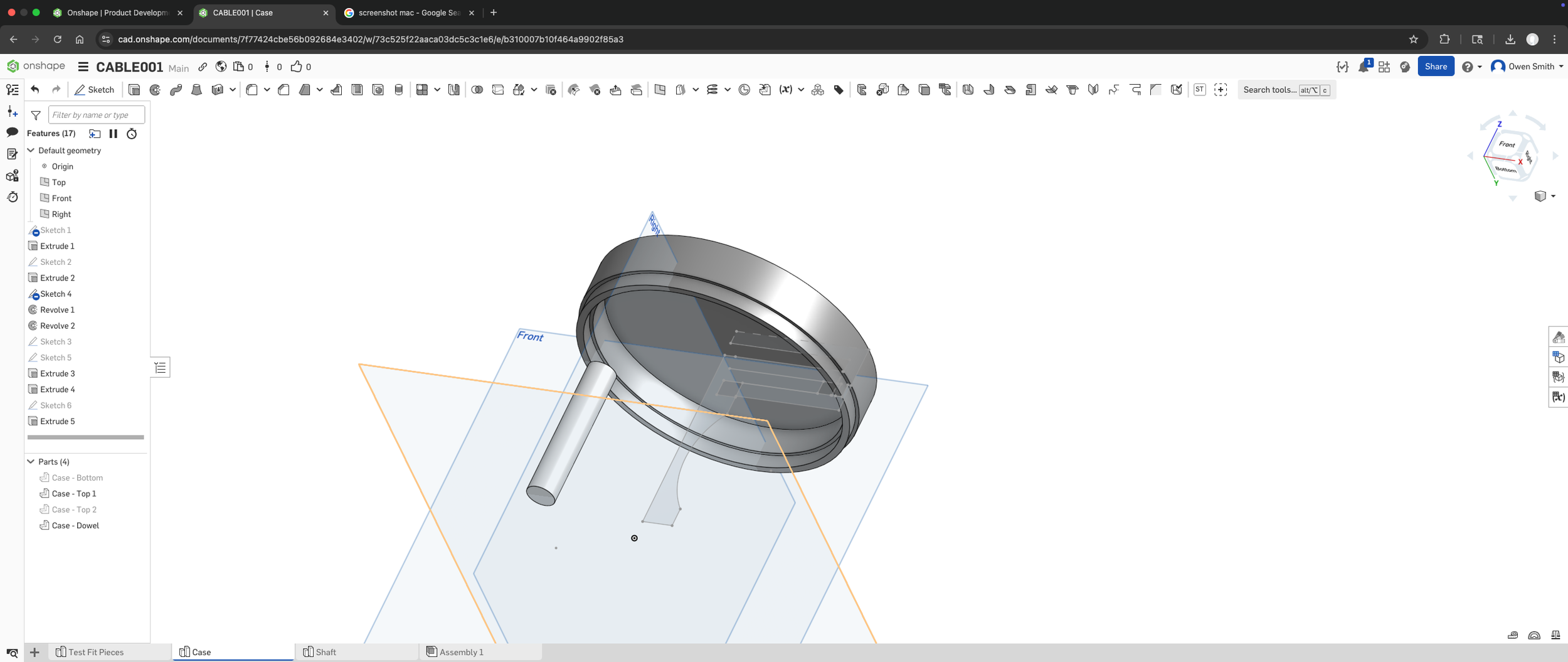

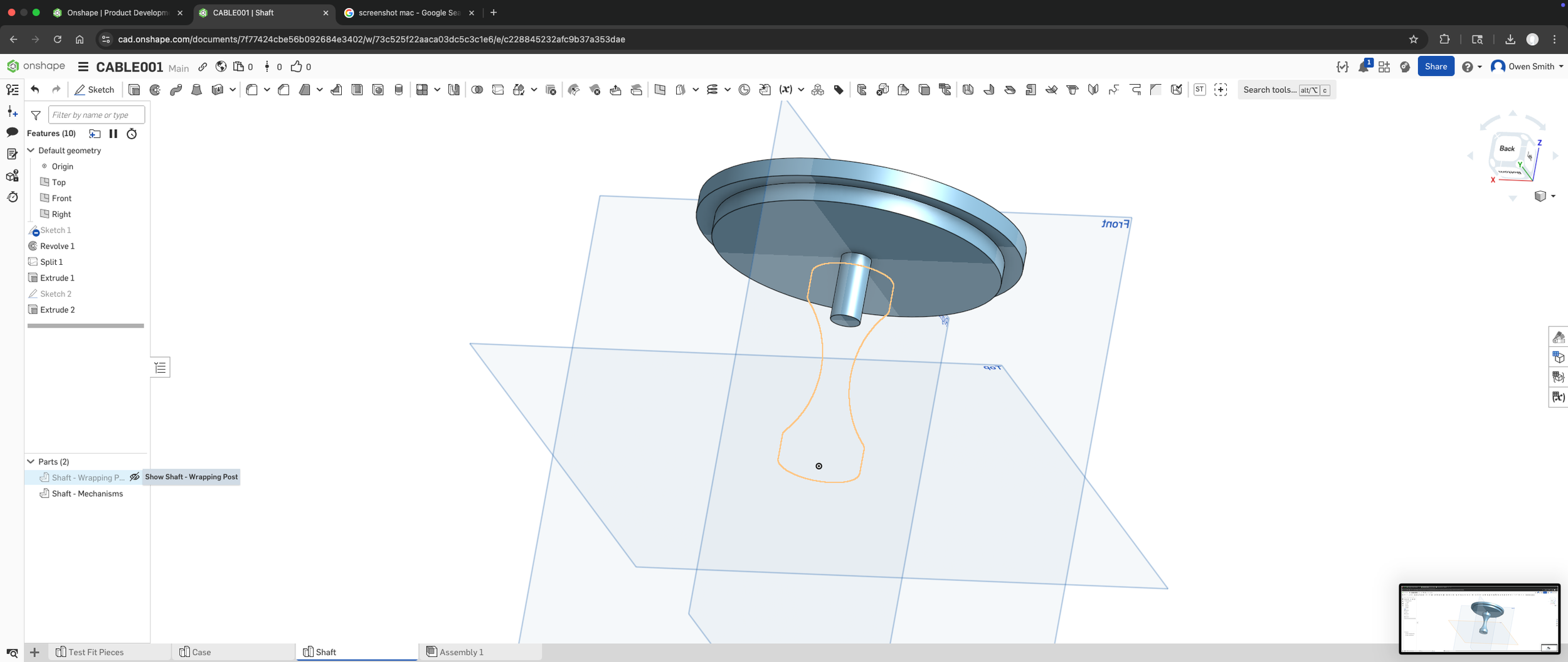

V2 Basic Shape / Concepts

Case

2 different heights of case

Clearance over top of spool wheel

reduced wall height for pawl to interface with teeth

Addition of a grid of holes

Allow for variable pin placement to accept spring + cam to optimize tension and ratchet interface (more on this later)

Pin going through center

Will house screw on top to fix top of case

Likely M2 or M3

Centerpoint of torsion screw

Spool Wheel

Tall enough to accept top screw + torsion spring

Center recess for torsion spring

Free-handed ratchets - this will be largely based on feel of mechanism

Pawl + Spring Mechanism

Pawl Shape will change based on feel

Grodded layout to determine angle / amount of torsion needed to interface pawl with teeth

Test Print 1 Goals:

Figure out proper tensioning of pawl

Determine if spring interface with wheel is sifficient + Durable

Make sure M3 screw / insert work properly

Sort out how to lock one end of the cable so the retractible portion remains on one side.

Figure out of tolerances for moving components ok

Possible use of bearings if necessary will require a redesign

Changes from V1

Opting for a side entry design to reduce bulky design

Integrating spring within spool wheel instead of stacked design